Chef's Knives

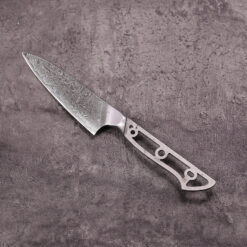

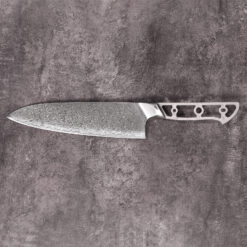

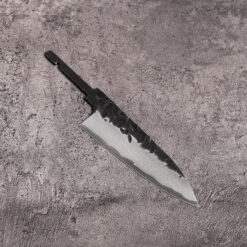

The Best Pre-made Kitchen Knife Blade Blanks without Handle

The Best Pre-made Kitchen Knife Blade Blanks

The pre-made kitchen knife blank is perfect for DIY projects, they are ready to go you can simply add your favorite material to the handle, laser engraving your name or your brand on them. Many DIY projects are failed because the knife maker didn’t have enough experience and overlook the difficulties of their project. So, starting a knife-making project with a high-quality knife blank is a practical solution for pros and beginners.

Knife Making Kit

Knife Making Kit

Knife Making Kit

Knife Making Kit

Custom Knives

Knife Making Kit

Bread Knives

Knife Making Kit

Honesuki Knives

Knife Making Kit

Knife Making Kit

Knife Making Kit

Japanese Knives & German Knives

Japanese knives: Japanese knives are characterised by their lightness and sharpness. Japanese knives have a knife angle of mostly 12 -16 degrees and a hardness of over HRC60.

German knives: German knives are characterized by precision and durability, German knives are generally at an angle of 20 degrees, very easy to maintain, and the hardness is between HRC55-58.

What makes a knife a good knife? In fact the quality and performance of a knife is determined by two main aspects, one is the process of making the knife and the other is the material of the knife.

What is steel?

Steel is an alloy. It is basically a combination of iron and carbon and when no other element is present is called plain carbon steel. Usually, today’s steels contain small amounts of various elements such as Silicon, Manganese, and Vanadium that give to the steel different properties. For example, steels that have added chromium over 12-14% are considered corrosion resistant (labeled as “stainless steels” in the market) or steel that contains manganese have increased strength, toughness and hardenability.

Hardness, in general, is a good thing. The harder the blade the better the edge has (edge stability and edge holding). It is preferably measured using the Rockwell scale (HRC) and commercial kitchen knives typically range between 55-60 HRC. Usually handmade kitchen knives are hardened more to the 60-65 HRC range or even higher.

What are the properties of steel?

Strength: The ability to resist applied forces.

Hardness: The ability to resist permanent deformations.

Toughness: The ability to resist prior to fracturing (also resistibility to cracks /chips when used in heavy duty applications). The harder the steel the less tough it is.

Wear Resistance: The ability to resist wear and abrasion.

Corrosion Resistance: The ability to resist corrosion as a result of reaction with external elements.

Edge Retention: The ability to hold an edge without re-sharpening

Hardenability: The ability of a steel to be hardened through the heat-treating process

Which is the best steel for kitchen knives?

There is no perfect steel. There is the best steel for the work needed.

Steel performance depends on many factors and many of its properties are inversely proportional to each other.

With that said, when an element is added to the recipe- because we want a specific property – we inevitably sacrifice another one and its properties. Subsequently, we have to trade-off some properties and usually this is between hardness/edge retention and toughness. The bet in knifemaking is to find the best steel, geometry and heat treatment for your knife, in order to perform optimal in specific tasks.

There are some very important elements in knife making that give steel specific properties. Below you will find some of the most important.

Steel elements

Carbon: Increases hardness and strength. Over 0.5% carbon in an alloy is considered “high-carbon”.

Nitrogen: Substitute of Carbon. New technologies use nitrogen in place/ complimentary of carbon to increase hardness.

Chromium: Increases hardenability, corrosion resistance and wear resistance, but in high amounts decreases toughness. Over 12%, a steel is considered “stainless”.

Molybdenum: Increases hardenability, tensile strength, and corrosion resistance.

Nickel: Increases toughness, hardenability and corrosion resistance.

Niobium: Forms very hard but also very small carbides that lead in wear resistance. Keeps the grain small and refines structure.

Vanadium: Increases hardenability and promotes fine grain structure.

Tungsten: Increases wear resistance and is the second strongest carbide* former after vanadium.

*carbide: A compound of carbon and another element.

Here are some good options and commonly used for kitchen knives.

D2 / SKD11 – Stainless powder steel

D2 and SKD11 are names for the same powder steel. Its fine structure and good distribution of the elements make it possible to add more alloy elements than in regular stainless steel. That increases the hardness and cutting characteristics. D2 / SKD11 steel is slightly harder than SG2 / SGPS steel but because of the lower chrome content less rust resistant too. It often is called a semi stainless steel type.

MC66 / ZDP-189 – Stainless powder steel

ZDP-189 is called Zwilling J.A. Henckels MC66 steel and is the hardest stainless powder available at the time of writing (2012). It has the highest content of alloy elements of all powder steel types. Zwilling J.A. Henckels reaches a hardness of ca. 66 Rockwell C. ZDP-189 is very hard and durable, but more sensitive to corrosion and breakage of pieces than for example SG2 / SGPS and D2 / SKD11. In addition, ZDP-189 is difficult to sharpen.

SG2 / SGPS – Stainless powder steel

SG2 and SGPS are two names for the same powder steel. Its fine structure and good distribution of the elements makes it possible to add more alloy elements than in ordinary stainless steel. That increases the hardness and cutting characteristics. Nevertheless, the rust resistance of SG2 / SGPS is higher than that of VG10 steel.

Just like VG10 steel SG2 / SGPS steel is almost always used laminated. The damask steel used is always slightly harder than for VG10 knives, which benefits the scratch resistance.

VG10 (V-Gold 10) – stainless steel

VG10 is a stainless steel type with a – for stainless steel – high carbon percentage, i.e. 1%. This makes VG10 harder than most stainless steel types. The cutting characteristics are very good and VG10 is easy to sharpen razor sharp.

The rust resistance is overall good, but VG10 steel is more sensitive to pit corrosion than steel types with lower carbon content. When a rust spot occurs it must be ground/polished off to prevent that the corrosion continues. Regular sharpening of the edge prevents corrosion that can lead to breakage of pieces.

Never place knives in VG10 steel in the dishwasher and never leave them in the sink. Softer steel types are more forgiving.

VG10 steel is almost always laminated between 2 layers of softer and more stainless steel. That increases rust resistance and makes the production process easier. Sometimes pure stainless steel layers are used which results in a 3 layered blade and sometimes 16 or 32 layered damask is used which results in a 33 or 65 layered blade.

Another name for VG10 steel is ‘V-Gold 10’ The indication ‘Cobalt steel’ is sometimes used too, but that could of course also designate another steel type with Cobalt.

Hitachi is the manufacturer of VG10 steel, but often the name of the Takefu factory is used, that markets the steel in laminated format.

X50CrMoV15- stainless steel

X50CrMoV15 is the most commonly used stainless steel type for kitchen knives by a.o. German manufacturers. It is a good steel type for a very wide public. The rust resistance is high and the cutting characteristics are perfect.

Excellent for family use and professional use where not everyone is careful with the knives. For info: X stands for stainless, 50 for 0.50% carbon and 15 for 15% Chrome. In addition the steel contains small quantities of Molybdene and Vanadium to improve the grain structure and durability.

Heat Treatment

Steel acquires its properties (see above) through heat treatment. In this procedure the steel is heated in high temperature (called austenitizing temperature) where it changes its structure and then it is quenched in a medium (oil/water/air) in order to “lock” and keep that structure. The new phase of the steel (which is now called martensite) gives us the desired properties of the steel , hardness, strength etc. Then it is tempered (re-heated into lower temperature) to release stresses and define hardness according to our needs. Also, almost all steels benefit from an extra treatment, called “cryo teatment”, where the steel is placed, before tempering, in liguid nitrogen (or even dry ice / alcohol solution) dewar for couple of hours. This procedure, which badly is considered by many an extra (due to cost), helps extract even more hardness ( through carbide precipitation/reduced retained austenite) .

The procedure may sound easy, but it requires perfect timing and preparation as is one of the most crucial steps in the knifemaking process. It requires countless hours of testing, knowledge of metallurgy and proper equipment.

Damascus-caldding steel

How to care and use your kitchen knives

1. Sharpen your knives regularly: A sharp knife is safer than a dull knife because it takes less effort to cut ingredients with a sharp knife, is more precise and less likely to slip, and your hands are less likely to get tired.

2. When a knife falls: Never try to catch a knife when it falls! Doing so could result in serious injury.