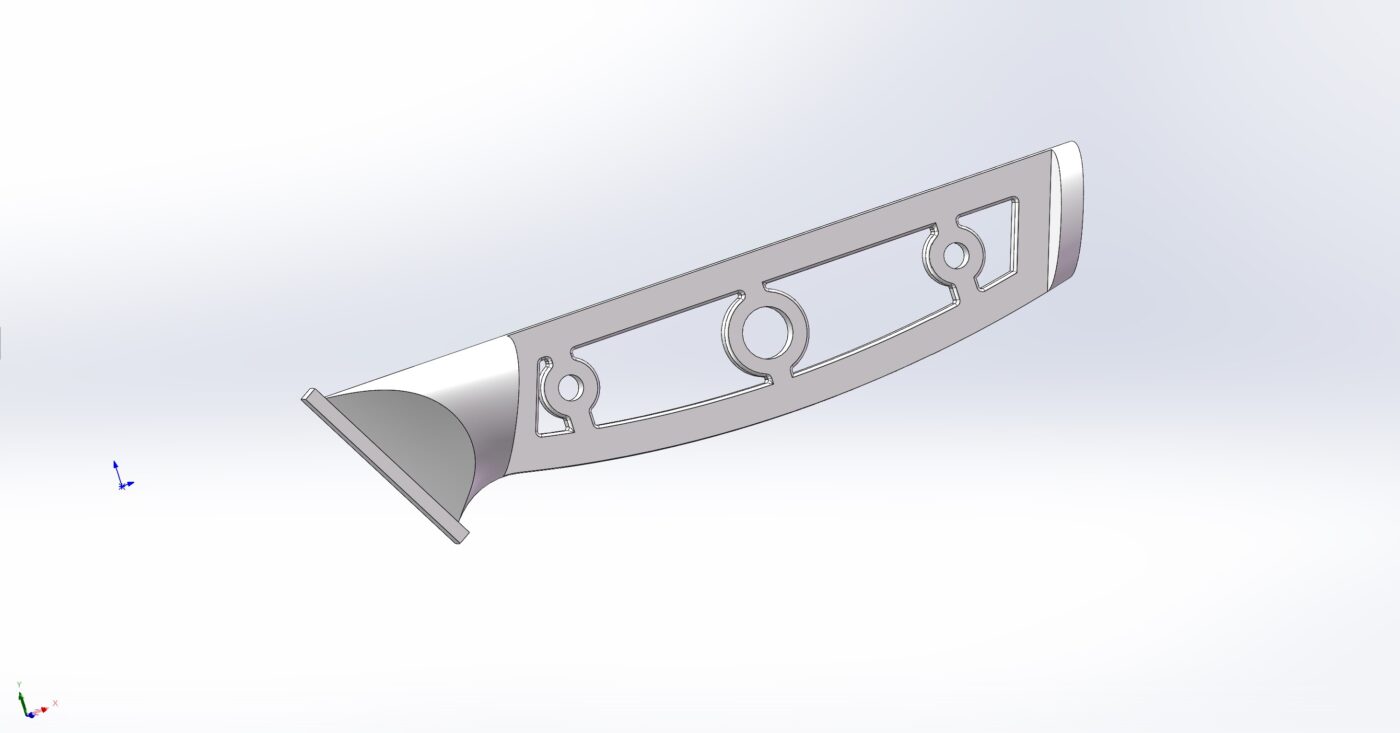

3D Printing the Design

Before committing to steel production, we create detailed 3D printed prototypes. This crucial step allows us to test the knife’s feel, balance, and functionality. Our clients can review physical samples of custom knives and OEM products, ensuring complete satisfaction with the design before mass production begins.