Kitchen Knives Manufacturer

Is CPM MagnaCut the Best Steel for Your Next Knife?

Imagine a steel that doesn’t just perform but redefines what a knife can do. CPM MagnaCut, crafted by Crucible Industries and designed by metallurgist Dr. Larrin Thomas, is that game-changer. Built from the ground up for knives, this powder metallurgy stainless steel blends toughness, edge-holding grit, and rust-defying prowess in a way that’s turning heads among knifemakers and enthusiasts alike. Here’s why MagnaCut is carving out a new standard for blades.

What Makes CPM MagnaCut Special?

CPM MagnaCut is a powder metallurgy (PM) stainless steel produced through Crucible’s advanced Crucible Particle Metallurgy (CPM) process. This involves spraying molten steel into a fine powder, then compressing and sintering it into a solid billet, creating a uniform microstructure with fine, high-hardness carbides. With a composition of 1.15% carbon, 10.7% chromium, 4% vanadium, 2% molybdenum, 2% niobium, and 0.2% nitrogen, MagnaCut eliminates chromium carbides—brittle particles that weaken other stainless steels. Instead, it relies on small vanadium and niobium carbides (totaling 8% by volume), mirroring the toughness of non-stainless CPM 4V while boosting corrosion resistance. This unique design delivers a steel that excels in knifemaking and beyond.

Key Properties of CPM MagnaCut:

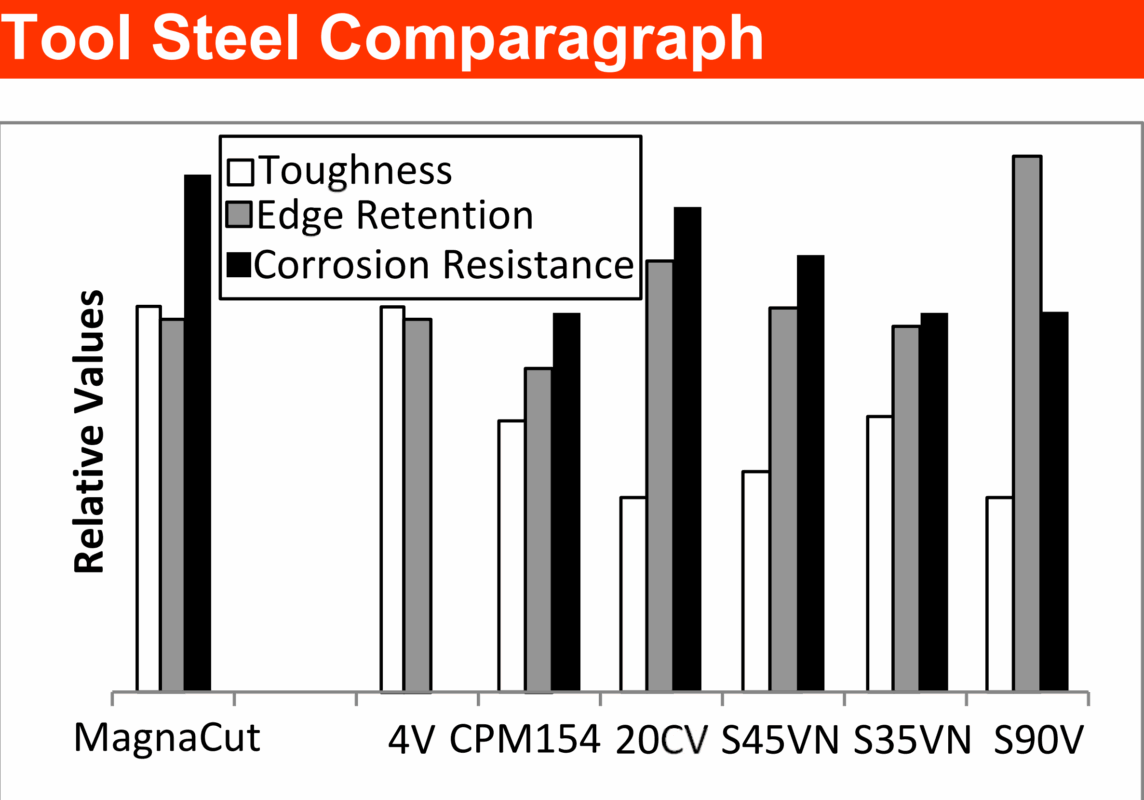

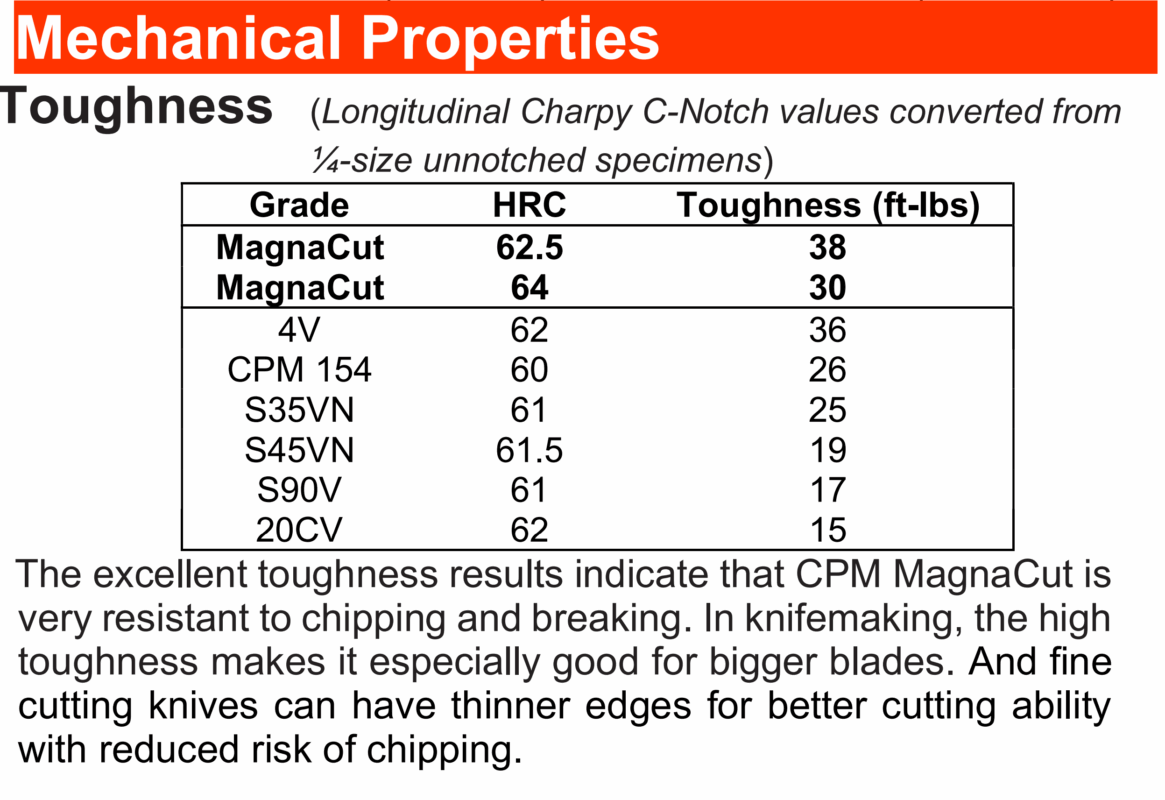

- Exceptional Toughness: MagnaCut achieves remarkable toughness, with longitudinal Charpy C-Notch values of 38 ft-lbs at 62.5 HRC and 30 ft-lbs at 64 HRC, surpassing steels like S35VN (25 ft-lbs at 61 HRC) and S45VN (19 ft-lbs at 61.5 HRC). This resistance to chipping and breaking allows for thinner edges on fine cutting knives and robust durability for larger blades, ideal for heavy-duty tasks.

- Superior Edge Retention: In CATRA testing, MagnaCut at 62.5 HRC scores 135% of 440C’s edge retention, outperforming CPM 154 (120%) and S35VN (130%) while closely trailing premium steels like S90V (195%). Its fine carbide structure, driven by vanadium and niobium, ensures long-lasting sharpness under demanding use.

- Outstanding Corrosion Resistance: By eliminating chromium carbides, MagnaCut maximizes the effectiveness of its 10.7% chromium content, achieving corrosion resistance superior to S35VN and S45VN in 1% saltwater spray tests (72 hours). It approaches the rust resistance of nitrogen-based steels, making it a top choice for humid or marine environments.

- Ease of Sharpening: Despite its high wear resistance, MagnaCut’s fine microstructure allows for easier sharpening than ultra-hard steels like S90V, offering a practical balance for knifemakers and users.

Heat Treatment Recommendations

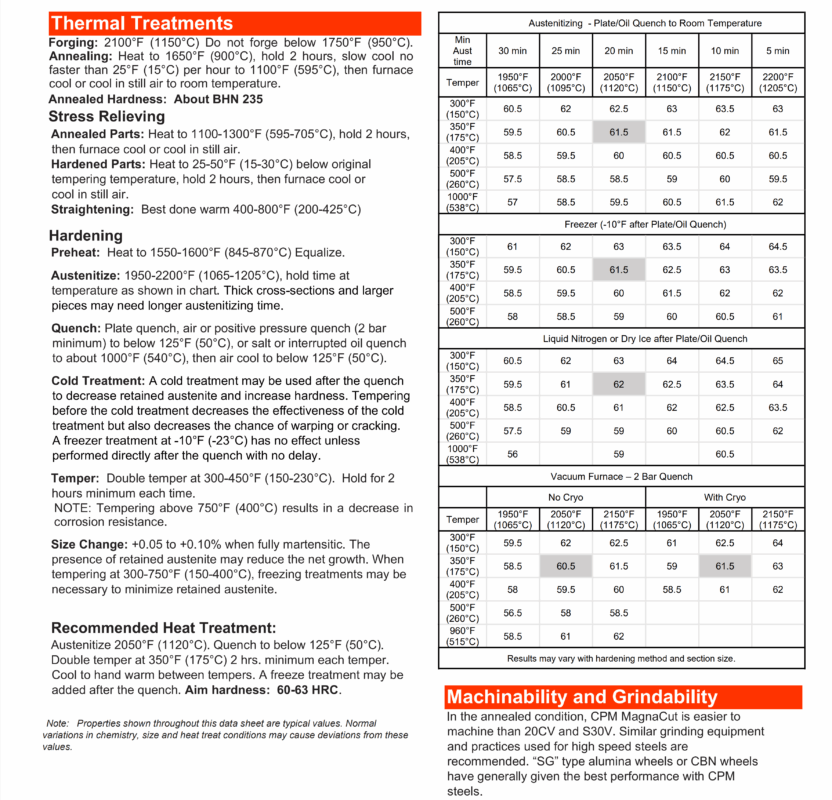

To maximize MagnaCut’s performance, precise heat treatment is crucial. The recommended process is:

- Preheat: Heat to 1550–1600°F (845–870°C) and equalize.

- Austenitize: Heat to 2050°F (1120°C) for 20 minutes for thin sections, up to 30 minutes for thicker pieces. Higher temperatures (up to 2200°F/1205°C) increase hardness but may reduce toughness.

- Quench: Use plate, air, or positive pressure quench (minimum 2 bar) to below 125°F (50°C), or interrupted oil quench to 1000°F (540°C), then air cool to below 125°F.

- Cold Treatment (Optional): Apply a cryogenic treatment immediately after quenching to reduce retained austenite and boost hardness (e.g., 64.5 HRC at 2200°F with cryo). A freezer at -10°F (-23°C) is ineffective unless done post-quench.

- Temper: Double temper at 350°F (175°C) for 2 hours each, cooling to hand-warm between tempers. This yields 61.5–62.5 HRC, balancing toughness and edge retention. Tempering above 750°F (400°C) reduces corrosion resistance.

This process achieves a hardness of 60–63 HRC, with size changes of +0.05 to +0.10% when fully martensitic. For knifemakers, straightening is best done warm at 400–800°F (200–425°C).

CPM MagnaCut isn’t just a steel—it’s a revolution in knife-making. Its blend of toughness, edge retention, corrosion resistance, and grindability sets a new benchmark, making it ideal for EDC, kitchen, outdoor, or custom knives. From its innovative carbide-free design to its proven performance, MagnaCut empowers knifemakers to create blades that cut sharper, last longer, and thrive in any environment. Explore our MagnaCut knives and join the future of cutlery today!

For more technical details, visit Dr. Larrin Thomas’ blog, Knife Steel Nerds, or read his book, Knife Engineering.