Kitchen Knives Manufacturer

What’s Damascus-Clad Kitchen Knife?

Steps of Ancient Damascus Forging

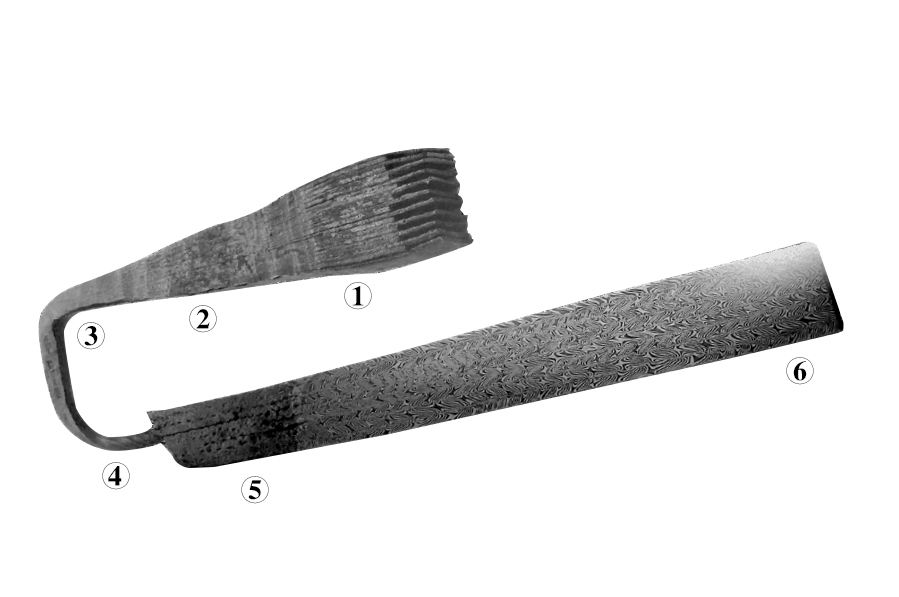

1.Laminating Layers

Several layers of contrasting steels are layered together and fixed with welds or wire wrap.

2.Initial Forging

Under extreme heats in excess of 1200 degrees, layers are fused with a hammer.

3.Forge extrude metal

Continually heating the steel, it is further hammered to compress and extrude material.

4.Twist billet

To create a pattern within the layers, the whole billet is twisted, entwining the layers along the billet.

5.Laminate several twisted billets

This duplicates the twisted pattern.

6.Forge to thickness

After forge welding layers together, the billet is drawn down to thickness, grinded and acid etched.

But for modern kitchen knife production line, people use clad stainless steel + sand-blasting to make sure the knife is FDA approved products.

Damascus Clad Steel (Damascus Steel)

In its modern form, Damascus steel is an alloy consisting of multiple visible layers produced in combination with a core steel. The base material used for the production of modern Damascus steel derives from steels with various contents of accompanying elements. The combination of steel grades with contrasting properties allows the production of particularly hard and at the same time flexible steels.

Related Post about Clad Steel:

Damascus Steel with 9Cr18, 10Cr15, VG10, AUS8, and AUS10 Cutting Core

Ice tempered and hardened to Rockwell C56˚–C60˚, the stainless steel holds the razor sharp edge of the blade longer than any other steel and resists rust, stains and corrosion.