Kitchen Knives Manufacturer, Kitchen Knives Supplier, Knife Distributors, Premier Kitchen Knives Supplier, Private Label Knife Manufacturers

Affordable High Performance Knives with DC53 Steel

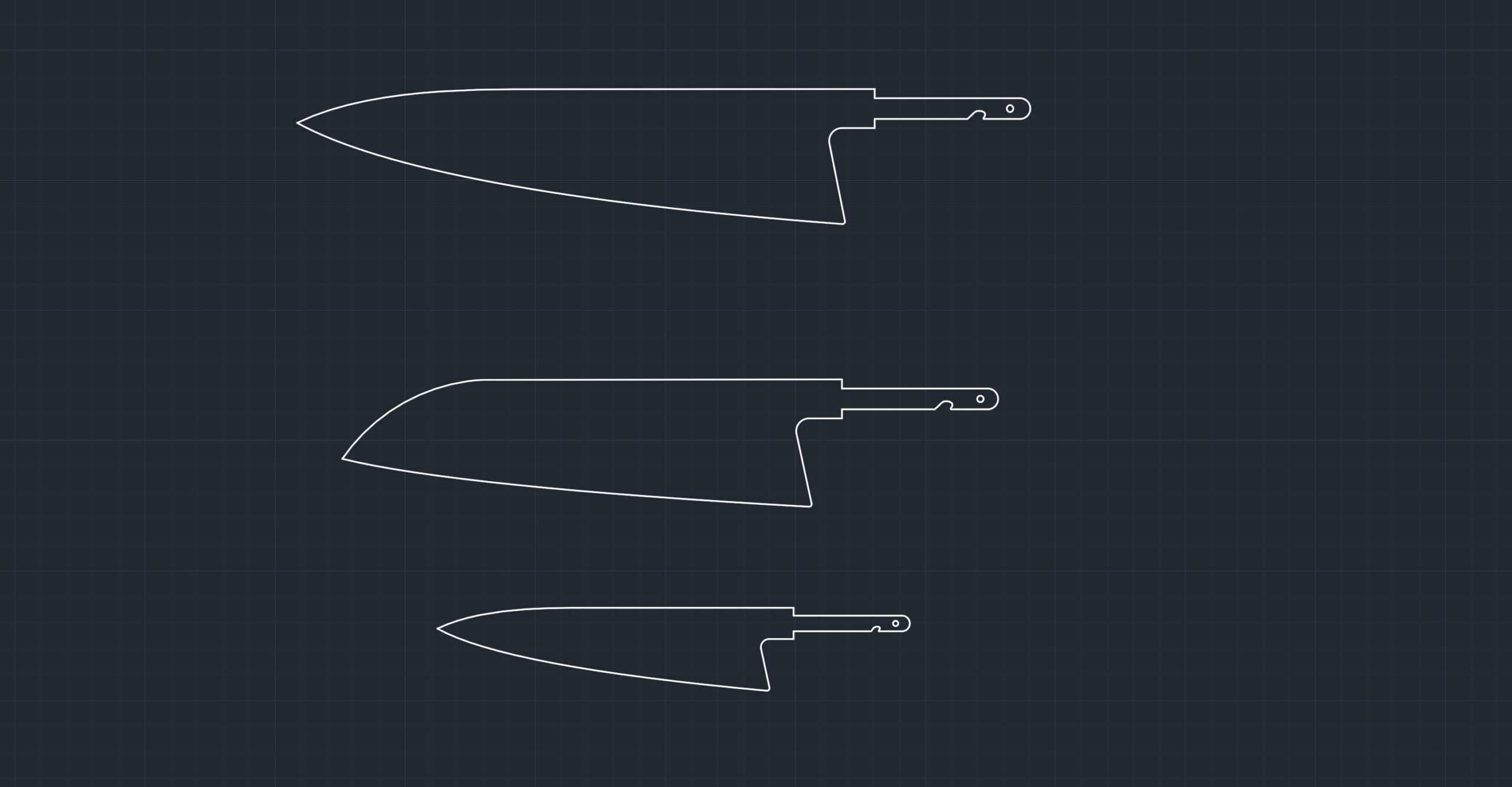

We will be developing three Japanese-style knives made from DC53 steel with a Nashiji finish. Stay tuned!

Affordable High Performance in Knife Steel

When it comes to kitchen knives, steel is everything. For years, steels like VG10, AUS-10, and SKD11 have dominated the market. But now, a new contender is stepping into the spotlight: DC53 steel.

At WholesaleChefKnife.com, we’re excited to introduce our upcoming DC53 knife series — designed for chefs and serious home cooks who demand the very best.

What Makes DC53 Steel Special?

DC53 is not just another tool steel. It was engineered to outperform SKD11 (D2 equivalent) in toughness, hardness, and wear resistance. Here’s why it matters for knives:

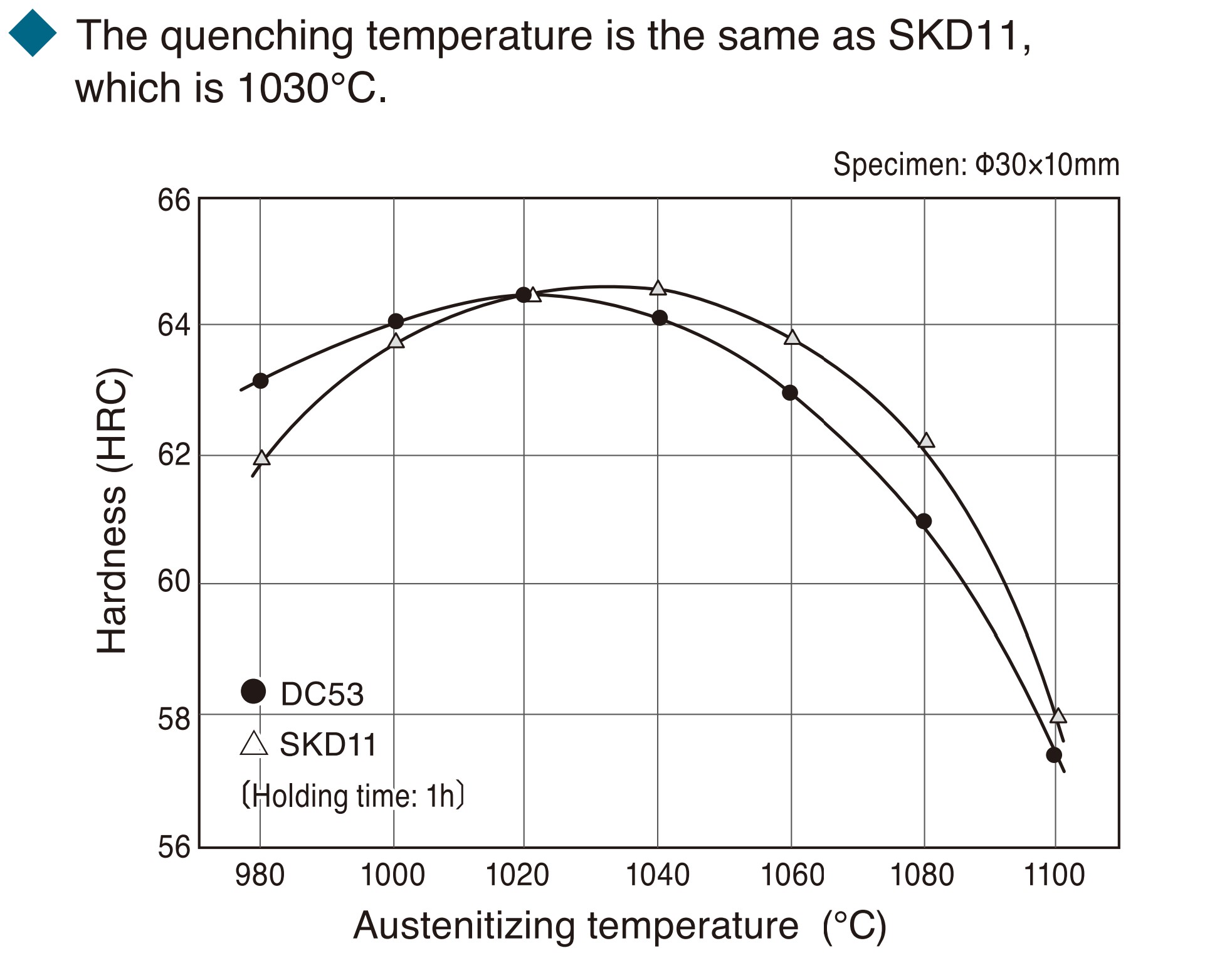

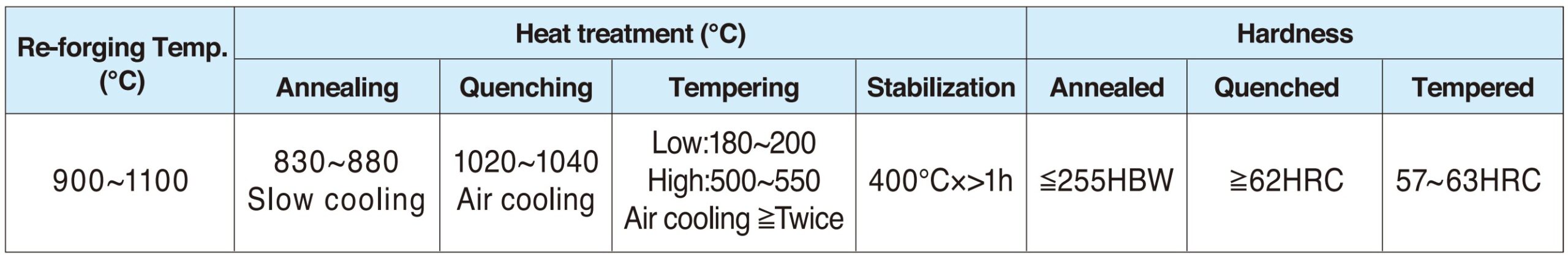

- Hardness: Up to 62–63 HRC after heat treatment — meaning a sharper edge that lasts longer.

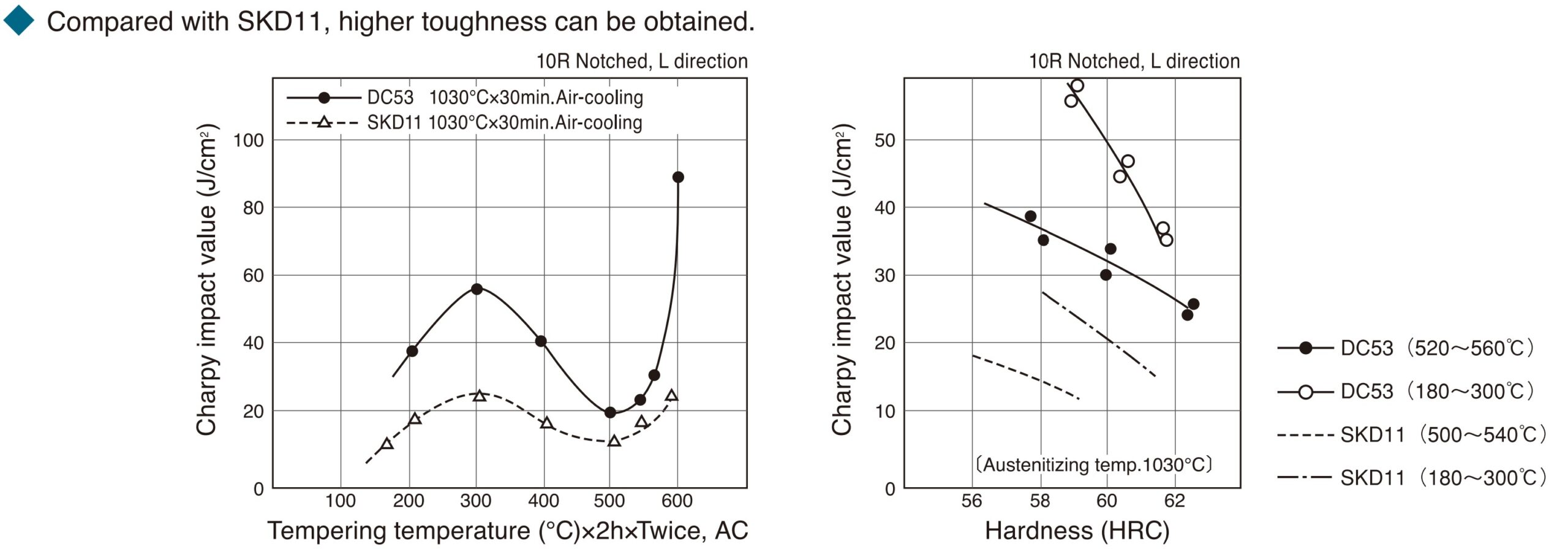

- Toughness: Twice as tough as SKD11, reducing the risk of chips and cracks.

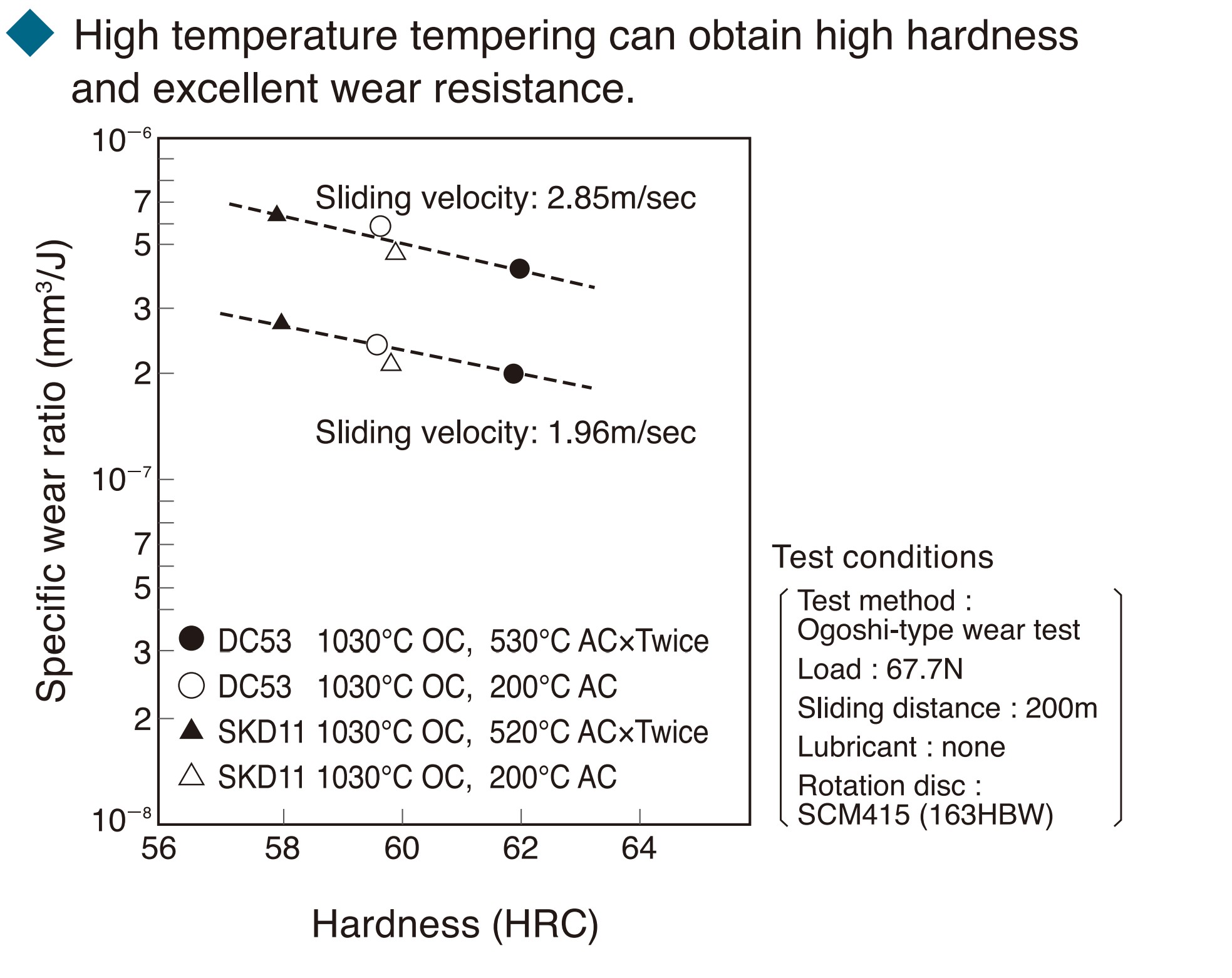

- Wear Resistance: Excellent edge retention, even under heavy use.

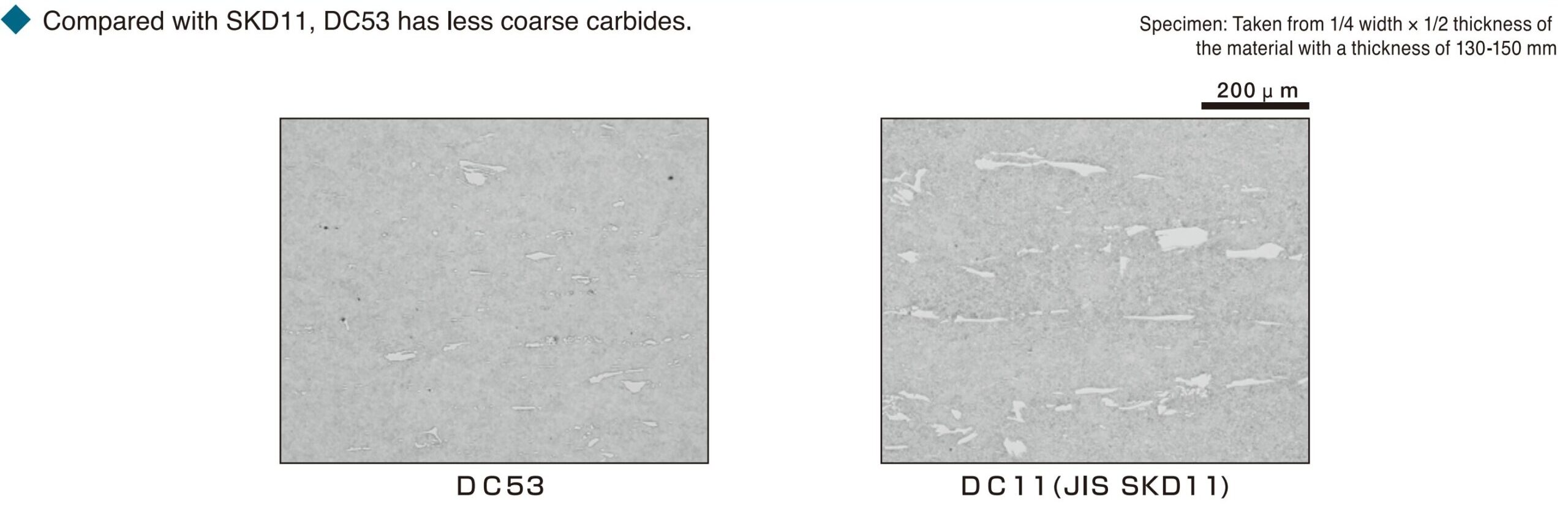

- Fine Carbide Structure: Smaller carbides mean a smoother, stronger edge that resists micro-chipping.

- Dimensional Stability: Less distortion during heat treatment, ensuring consistent blade geometry.

In short: DC53 combines the edge retention of high-hardness steels with the toughness of more forgiving alloys — the best of both worlds.

Heat treatment process for DC53

Why DC53 Is Perfect for Knives?

For chefs, the steel’s properties translate into real-world benefits:

- Longer edge life → fewer sharpenings, more time cooking.

- Reduced chipping → confidence when cutting through harder ingredients.

- High polishability → blades with a razor-sharp, mirror-like finish.

- Durability → knives that last for years, even in professional kitchens.

⚖️ Performance vs. Price: Why DC53 Makes Sense

- M390 and Blue/White Paper steels are elite performers, but knives made from them can cost 3–5× more than DC53.

- The real-world performance gain is not equal to the price jump. For most chefs, DC53 delivers 80–90% of the performance at a fraction of the cost.

- DC53’s sweet spot: It combines the edge retention of high-hardness steels with the toughness of more forgiving alloys, making it a practical choice for both professionals and serious home cooks.

Our Recommended DC53 Knife Lineup

We’re starting small — just four essential models that cover 95% of kitchen tasks:

1. 8″ Chef’s Knife (Gyuto) – The all-purpose workhorse.

2. 5″ Petty Knife – Perfect for fruit, herbs, and precision cuts.

3. 7″ Santoku – A versatile Japanese-style knife for vegetables, fish, and meat.

This “Core Four Collection” showcases DC53’s strengths without overwhelming buyers. As demand grows, we’ll expand into specialty knives like nakiri, bread knives, and sashimi blades.

How to Choose the Right Knife Steel?

- If you want easy maintenance → AUS-10 or VG10 (stainless).

- If you want traditional Japanese sharpness → Blue or White Paper (but be ready for rust and higher cost).

- If you want ultimate edge retention and don’t mind paying premium → M390.

- If you want professional performance at an affordable price → DC53 is the smart choice.

DC53 steel offers a rare balance: hardness, toughness, and affordability. While other steels may cost many times more, the performance increase is not proportional to the price. That’s why we believe DC53 is the future of chef knives — and why our upcoming DC53 knife series at WholesaleChefKnife.com is designed to give chefs the best value in the kitchen.

👉 Stay tuned for our launch — and discover why DC53 is the steel you didn’t know you needed.