Kitchen Knives Manufacturer

Best Custom Made Damascus Steel Kitchen Knife Maker

Imagine that you’ re trying to make a set of kitchen knives. Excited about your idea for a new knife, but struggling with a supply chain problem. Don’t worry, we’re here to help you.

WCK offers complete solutions.

We have strong and dedicated internal resources in design, engineering, project and account management and quality control.

Project Review

Our team integrates with yours to serve as partners throughout the product life cycle, starting from the initial concept stage. Whether you have a new product idea or are looking to solve a current supply chain problem, the project review phase is an integral part of getting to know you and your project goals.

In our initial consultation, we analyze your business plan and collaborate to define clear goals and production timelines with full transparency. We will discuss your Intellectual Property concerns from the beginning and will incorporate them into our project strategy.

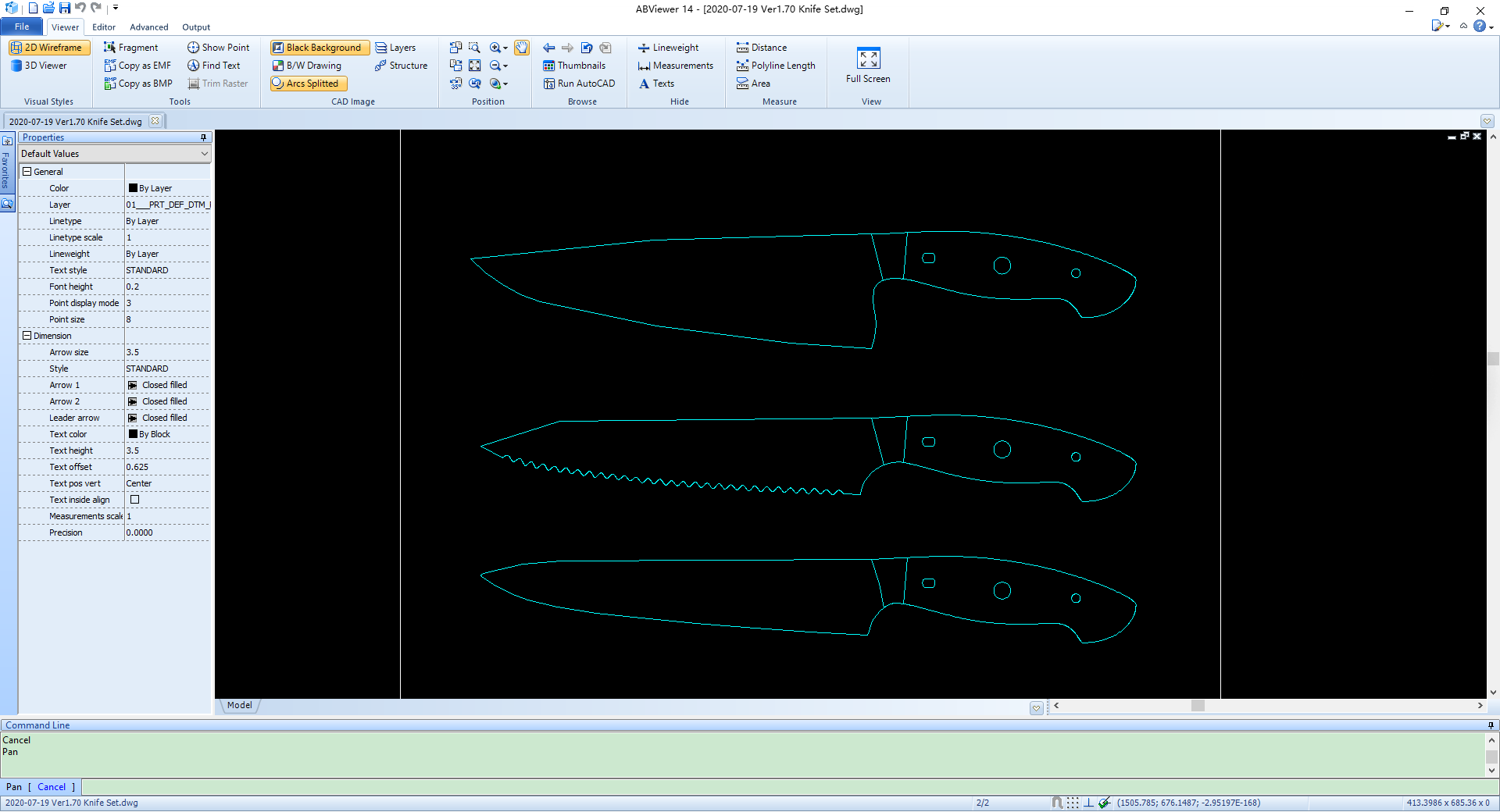

Industrial Design & Engineering

We focus on product functionality and price competitive costs without sacrificing quality materials and attention to detail. Our product team guides you through aesthetic, functional and material design options that lead directly into the 2D/3D CAD modeling process.

We optimize your designs specifically for manufacturing success using an engineering practice called Design for Manufacture (DFM). Our integration with established manufacturing partners and deep cross-category knowledge, results in a shorter product development lifecycle, reduced manufacturing costs and overall quality enhancements.

Prototyping

With design files, the prototyping phase transforms your concept into a physical object. Prototypes can be strictly functional, aesthetic or a combination of both. Prototypes should be done early and often. Our team has access in specialized prototyping materials and techniques such as 3D Printing, SLA and FDM, machining, urethane casting, pilot molds, soft tools and prototyping techniques for electrical, cosmetic and aesthetic features.

Based on the stage of development your product is in, we can help you build a prototyping plan. Then we can incorporate modifications of product designs based on testing and feedback that we get from all stakeholders. Lastly, we iterate based on these modifications by including many prototyping options to produce fully formed, functional and quality prototypes.

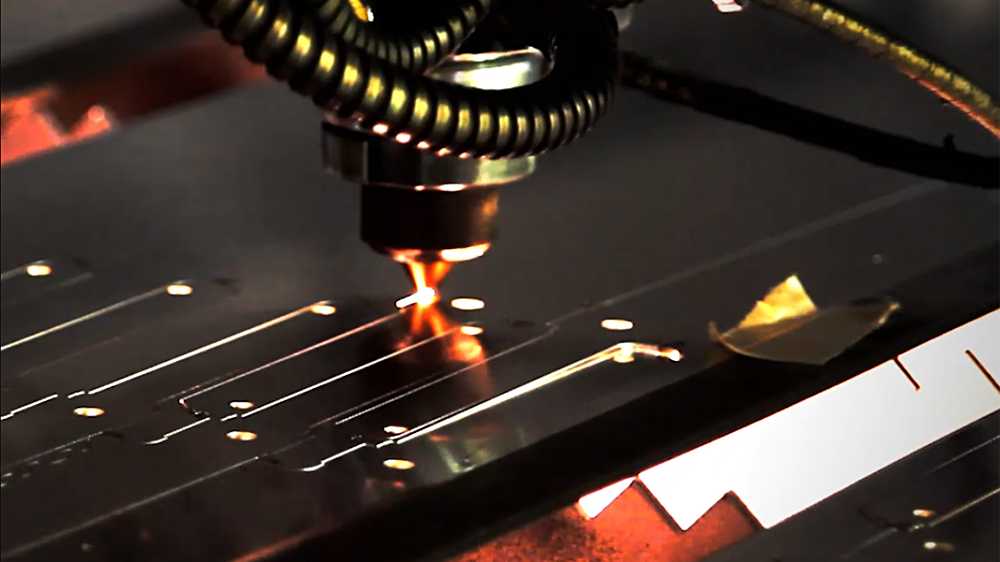

Main Processes for Manufacturing Kitchen Knives

After we finalize a blade, part, or component, we transfer the file to our CNC plasma cutter or to a laser cutting machine.

The blades are precision heat treated to a 58 to 62 Rockwell Hardness, depending on the blade design and function.

Bolster is welded to the blade. The bolster is a part of the handle that reinforces the junction between the blade and the handle.

Selected knife handle materials are cut, shaped and incorporated into each design.

Each knife is shaped, sanded, and polished using belt sanders, buffing wheels, and hand tools. The finishing process ensures comfort and balance.

This method of blade edging is utilized for the high class lineup. By doing the grinding pouring water on the whetstone, it is possible to avoid the production of friction heat and to increase greatly the smoothness and the cutting quality of blade tips.

QC AND Sharpness Test

Chuanghe has built a long-standing, trusted network of kitchen knife manufacturers and suppliers in Yangjiang, and our clients benefit from economies of scale generated by our large manufacturing footprint.We focus on responsible manufacturing as we have worked with sustainable and recycled material factories, allowing us to stay competitive and add new capabilities to our network. Our team will help you simplify your procurement process by allowing you to consolidate your supply chain to a single point of contact for multiple factory locations. We will reduce the time and resources you need to manage your supply chain, allowing you to focus more on sales, marketing and innovation.We offer complete transparency into where your knives are being produced and encourage our clients to visit our factory at any time. As a final step, our logistics department helps streamline processes and simplify operations to facilitate getting products from our doorstep to yours.

Kitchen Knife Quality Control

We understand that every business has different priorities, but one fact is undeniable: knife quality is paramount. Our in-house team ensures product quality by placing a strict quality protocol in place. We take pride in production quality as it represents everything that we do. The process begins with supplier selection, project management, in production and final quality inspections. Our qualified team has solid experience working with multiple labs for safety and quality testing in a variety of product categories and markets. WCK is committed to meeting and exceeding our client’s quality expectations; we stand by our knife quality with a strong manufacturing warranty. Shop at Our Store Enjoy Wholesale Price.